ST powder coatings' Zinc-Rich Primer , EZ series, offers an outstandig protection against the corrosion of ferrous alloys surfaces. Taking advantage of the well known "sacrificial" properties of the metallic zinc (the main component of this primer), Zinc-Rich Primer is able to create a strong protective barrier against the natural and chemical corrosive actions.

Even in highly aggressive environments, the Zinc-Rich Primer will ensure a long- life of the coated objects.

This powder coating performs more effectively with an appropriate pretreatment cycle of the surface to be coated (zinc phosphating or sandblasting). For a better aestetic quality of the coated object, ST Zinc-Rich Primer could be overcoated with a polyester or an epoxy-polyester.

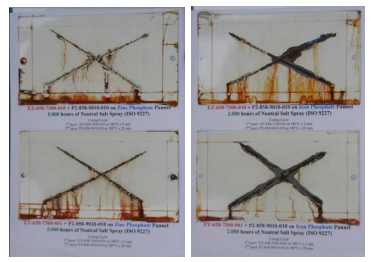

The following tables show the results of salt spray test for some speciments coated with ST Zinc Primer and overcoated with a white polyester.

Table 1: ST Zinc-Rich Primer’s corrosion resistance on Zinc Phosphated steel panels overcoated with white polyester.

| Primer Tested | 1.000 hours | 2.000 hours | 3.000 hours | 4.000 hours | 5.000 hours |

|---|---|---|---|---|---|

| Zinc Rich Primer | No blistering. No film detachment. | No blistering. No film detachment. | No blistering. No film detachment. | No blistering. No film detachment. | No blistering. No film detachment. |

Table 2: ST Zinc-Rich Primer’s corrosion resistance on Iron Phosphated steel panels overcoated with white polyester.

| Primer Tested | 500 hours | 1.000 hours | 2.000 hours |

|---|---|---|---|

| Zinc Rich Primer | No blistering. No film detachment. | No blistering. No film detachment. | No blistering. Film detachment near the crosscut (1-8 mm) |

An anti-corrosive powder coatings may experience some problems in intercoat adhesion under certain conditions of polymerization. For this reason, in order to ensure good interfacial adhesion between primer and finishing, in some cases it is not convenient to cure completely the primer but it is recommended to perform only a fusion by heating, for example 180°C for only 5 minutes or 120°C x 20 minutes. The primer is then completely cured in the subsequent stage, after the application of the second layer.

ST Zinc Rich Primer is also available in a version with reducing problems of interfacial adhesion related to the cure cycle of the primer. Interfacial adhesion tests performed in the laboratory gave optimal results, also after a cure cycle of the primer at 180°C x 20‘. Even the neutral salt spray test (ISO 9227) has given satisfactory results, with test duration of 2.000 hours.

Zinc Rich Primer has very good anticorrosive properties but it is subject to a small drawback: the sacrificial filler contained in it, which provides an excellent protection against the corrosion, influences negatively the toxicological profile. The Zinc Rich Primer, in fact, according to the laws governing the labelling and the transport of dangerous substances, is considered dangerous for the environment and the transportation is regulated by ADR.

For this reason ST Powder Coatings R&D Department has developed a new anticorrosive Primer not subject to labelling requirements. The properties of this new anticorrosive Primer, EY series, are due to a new innovative filler. The new filler performs its anticorrosion action not through a sacrificial process, as in the case of EZ series, but rather through an efficient "barrier effect".

The salt-spray results of EY series in comparison with EZ series are essencially the same, both on zinc phosphated steel panels and on iron phospated ones, as it is shown on the pictures on the left.

Search products

of this category

Search products